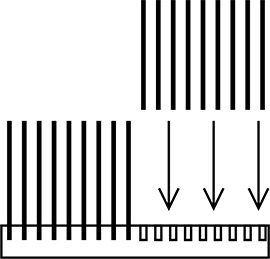

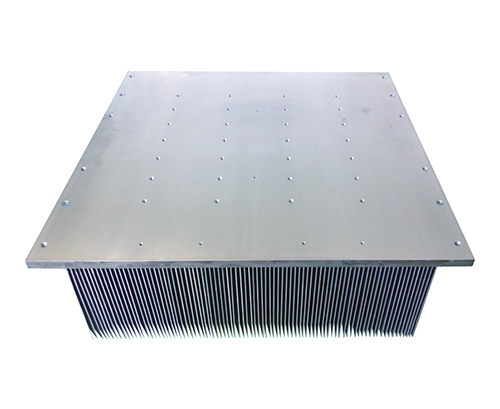

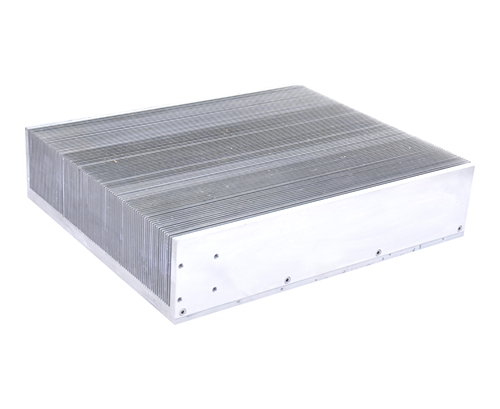

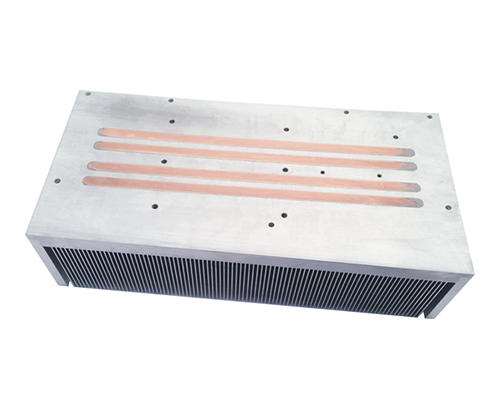

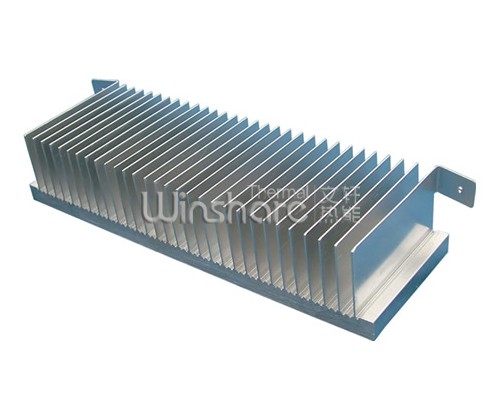

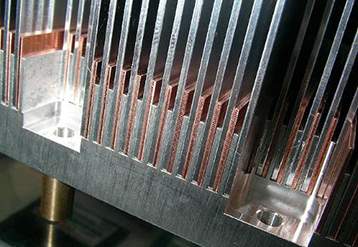

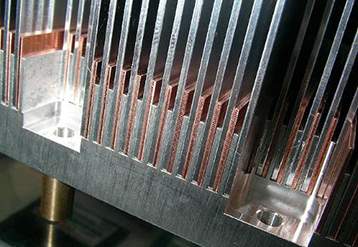

Stitched fin technique is a conventional high power heat sink manufacturing technique. Conventionally, this process is carried out by press-fit riveted fins. However, this usually leads to potential thermal risks such as matching clearance, loose fins, etc. To resolve this problem, Winshare Thermal launched several bonding techniques via our own technical innovations and these include highly conductive thermal epoxy bonding, welding, and soldering so as to greatly enhance the reliability and stability of cooling and avoid any potential risk.

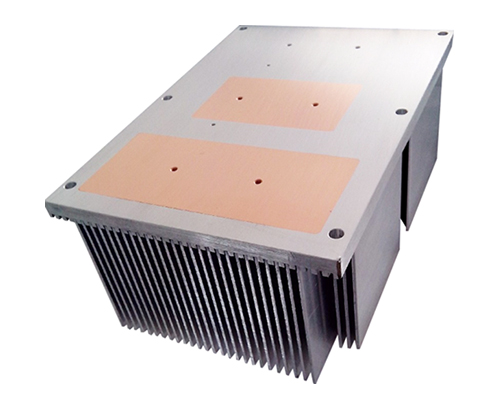

The features of stitched fin heat sinks include more fins per inch, smaller fin gap, and flexible profile height and width so that they are suitable for different sizes of application space. This type of heat sinks occupies a smaller volume and they are lightweight and therefore this technique is an ideal selection for cooling high power devices.

Stitched fin technique is a conventional high power heat sink manufacturing technique. Conventionally, this process is carried out by press-fit riveted fins. However, this usually leads to potential thermal risks such as matching clearance, loose fins, etc. To resolve this problem, Winshare Thermal launched several bonding techniques via our own technical innovations and these include highly conductive thermal epoxy bonding, welding, and soldering so as to greatly enhance the reliability and stability of cooling and avoid any potential risk.

Stitched fin technique is a conventional high power heat sink manufacturing technique. Conventionally, this process is carried out by press-fit riveted fins. However, this usually leads to potential thermal risks such as matching clearance, loose fins, etc. To resolve this problem, Winshare Thermal launched several bonding techniques via our own technical innovations and these include highly conductive thermal epoxy bonding, welding, and soldering so as to greatly enhance the reliability and stability of cooling and avoid any potential risk.